Metal, with its inherent strength and versatility, has long been a favored medium for artists, manufacturers, and designers. But beyond its structural properties lies a surface ripe with potential for intricate detailing. Enter laser marking, a technology that has revolutionized the way we interact with metal, transforming it from a blank canvas into a masterpiece of design and texture. This blog explores the art of laser marking metal, delving into its capabilities and showcasing the stunning results it can achieve.

What is Laser Marking?

Laser marking is a non-contact process that uses a focused beam of light to create permanent marks on a material's surface. Unlike traditional methods like engraving or etching, laser marking doesn't physically remove material in the same way. Instead, it alters the surface through various mechanisms:

Ablation: The laser removes material layer by layer, creating engravings or deep marks.

Discoloration/Annealing: The laser heats the material, causing a color change on the surface without removing material.

Etching: The laser creates a surface reaction, resulting in a frosted or etched appearance.

These processes allow for incredible precision and control, enabling the creation of highly detailed designs, intricate patterns, and even complex textures on a wide range of metals.

The Power of Precision: Intricate Designs

One of the most significant advantages of laser marking is its ability to produce incredibly intricate designs. From fine lines and delicate patterns to complex logos and detailed images, laser marking can achieve a level of detail that is simply impossible with traditional methods. This precision opens up a world of possibilities for:

Personalization: Creating custom engravings on jewelry, watches, and other personal items.

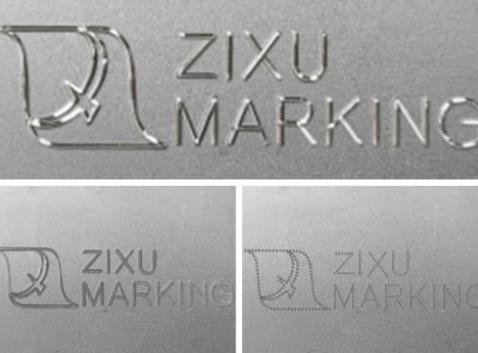

Branding: Marking logos and branding information on metal products with exceptional clarity and detail.

Decorative Art: Producing intricate artwork and designs on metal panels, sculptures, and other decorative pieces.

Micro-Marking: Marking extremely small components with precise identifiers, crucial for industries like electronics and medical devices.

Adding Depth and Dimension: Creating Textures

Beyond creating lines and patterns, laser marking can also be used to create a variety of textures on metal surfaces. By carefully controlling the laser's parameters, such as power, speed, and frequency, artists and designers can achieve a range of effects:

Crosshatching: Creating a textured surface with intersecting lines.

Stippling: Producing a textured effect with a series of small dots.

Surface Roughness: Creating a matte or textured finish by altering the surface's micro-structure.

Simulated Engraving: Achieving the look of traditional engraving without the material removal.

These textures can add depth, dimension, and visual interest to metal objects, transforming them into tactile and visually appealing pieces.

Applications Across Industries:

The versatility of laser marking has led to its widespread adoption across various industries:

Jewelry and Accessories: Creating personalized engravings and intricate designs.

Manufacturing: Marking parts with serial numbers, barcodes, and other identifying information for traceability and quality control.

Aerospace and Automotive: Marking critical components with durable and precise markings.

Awards and Recognition: Creating personalized plaques, trophies, and awards.

Art and Design: Producing unique and captivating artwork and decorative pieces.

The Future of Laser Marking:

As laser technology continues to advance, we can expect even greater precision, speed, and versatility in metal marking. Innovations like fiber lasers and advanced software are pushing the boundaries of what's possible, opening up new avenues for creativity and innovation.

In conclusion, laser marking has truly transformed the art of working with metal. Its ability to create intricate designs and textures has opened up a world of possibilities for artists, designers, and manufacturers alike. From personalized gifts to critical industrial markings, laser marking continues to redefine the way we interact with this versatile material.

Share this page with your family and friends.