In today's rapidly developing industrial era, the New Energy Vehicle Aluminum Profile, as an important structural material, is widely used in the design and manufacturing of various fields. Its unique characteristics enable it to strike a perfect balance between functionality and aesthetics, making it an ideal choice for modern engineering. This article will deeply explore the advantages, application fields, purchasing methods and future development trends of aluminium profiles, allowing you to have a more comprehensive understanding of the New Energy Vehicle Aluminum Profile.

I. Basic Characteristics of Aluminium Profiles

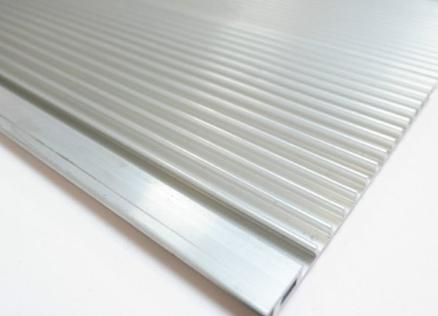

Aluminum profiles, as the name suggests, are materials made by processing aluminum alloys into specific shapes through extrusion or casting methods. It is highly favored in industrial design and manufacturing for its advantages such as light weight, high strength and corrosion resistance. The following are some main characteristics of aluminium profiles:

1. Lightweight: The density of aluminium is only one-third that of steel, which enables aluminium profiles to significantly reduce the overall weight of the structure while ensuring their strength. This characteristic is particularly important in fields such as aviation and automobiles where weight reduction is required.

2. Strength and Rigidity: Despite being relatively light, the strength and rigidity of aluminum alloy should not be underestimated. After certain heat treatment, the mechanical properties of aluminum profiles can be significantly improved, ensuring their stability in various applications.

3. Corrosion resistance: The surface of aluminum can naturally form an oxide film, which has excellent corrosion resistance and is suitable for use in various harsh environments. It is not prone to rust or oxidation.

4. Processability: Aluminum profiles are easy to process and can be processed in various ways such as forming, welding and painting, etc., to meet different design requirements.

5. Environmental friendliness: Aluminium is a recyclable material. The use of aluminium profiles also promotes the concept of sustainable development, which meets the modern society's demand for environmental protection.

Ii. The Wide Application of New Energy Vehicle Aluminum Profile

The New Energy Vehicle Aluminum Profile has been widely used in multiple industries due to its unique performance and flexible design. The following are some specific application examples:

Automated equipment

In the field of industrial automation, aluminium profiles are widely used as the frames and brackets of equipment. Its light weight and high strength make the movement and adjustment of the equipment more efficient. In addition, aluminium profiles can be flexibly transformed in structural design to meet the requirements of different equipment.

2. Robot framework

With the development of intelligent manufacturing and robot technology, aluminum profiles have gradually become an important component of robot structures. Robots need to have the characteristics of high strength and lightweight to enhance the flexibility and speed of movement, and aluminum profiles precisely meet these requirements.

3. Transportation and Logistics

In the transportation and logistics industry, aluminium profiles are widely used in the construction of shelves and conveying systems. Its corrosion resistance and lightness make the entire transportation process more efficient and also reduce maintenance costs.

4. Warehousing system

In warehouse management, aluminium profiles are used to design flexible storage rack systems, facilitating the rational utilization of warehouse space. Through modular design, the warehousing system can be adjusted at any time as needed to achieve higher space utilization.

5. Display and Advertising

In exhibition design, aluminium profiles, with their beautiful surface and modern appearance, have become the ideal choice for booths, advertising racks, etc. Aluminum profiles not only enhance the overall modernity and aesthetic appeal, but also facilitate transportation and handling.

Iii. Precautions for Selecting and Purchasing Aluminum Profiles

When choosing and purchasing the New Energy Vehicle Aluminum Profile, consumers need to consider multiple factors to ensure that the purchased product meets their own needs:

1. Material standards

When making a purchase, one should check the material standards of the aluminum profiles. Different aluminum alloy grades correspond to different strength and performance requirements, and the appropriate material should be selected based on specific applications.

2. Surface treatment

The surface treatment process of aluminium profiles directly affects their corrosion resistance and appearance. Common surface treatment methods include anodizing, spraying and electrophoresis, etc. Choosing the appropriate surface treatment method can increase the service life of aluminum profiles.

3. Dimensions and Specifications

The sizes and specifications of aluminium profiles are diverse, and the selection should be made according to the design requirements. Before purchasing, the requirements should be measured in advance and confirmed with the supplier.

4. Accessories and matching

When building a framework, the required accessories are equally important. Ensure that the purchased aluminium profiles are compatible with connectors, brackets and other accessories to enhance the stability and efficiency of the overall structure.

5. Price and After-sales Service

When choosing aluminium profiles, one should also pay attention to their prices and after-sales services. Choosing a supplier with a good reputation can ensure quality while enjoying excellent after-sales service and technical support.

Iv. Future Market Trends of Aluminum Profiles

With the continuous advancement of technology, the aluminum profile market is also developing steadily. The following are some trends for the future:

Research and Application of Silicon-aluminum Alloy materials

To improve the performance of aluminum profiles, many research institutions and companies are actively exploring the application of silicon-aluminum alloys, striving to enhance their strength and durability.

2. Intelligent manufacturing

The development of intelligent manufacturing technology will drive the production of aluminum profiles towards intelligence. Automated production lines will enhance production efficiency and reduce labor costs.

3. Green and environmentally friendly technology

Today, as environmental protection is increasingly valued, the production of aluminum profiles will develop in a more environmentally friendly direction, adopting renewable resources and more environmentally friendly processes to meet the requirements of sustainable development.

V. Summary

The New Energy Vehicle Aluminum Profile has played an indispensable role in modern engineering and industry with its characteristics such as light weight, high strength and corrosion resistance. Its wide application range and outstanding performance make it an ideal choice. Aluminum profiles are everywhere, from automated equipment and robot frames to transportation and warehousing systems. When choosing aluminium profiles, consumers should fully consider factors such as material standards, surface treatment, and size specifications. Meanwhile, in the future, the aluminum profile market will continue to move forward in the direction of intelligence and environmental protection along with the development of technology. Whether in terms of design innovation or structural flexibility, the New Energy Vehicle Aluminum Profile will play a greater role in future engineering applications.

New Energy Vehicle Aluminum Profile https://www.rongxinhao.com/New-energy-vehicle-aluminum-profiles.html

Share this page with your family and friends.